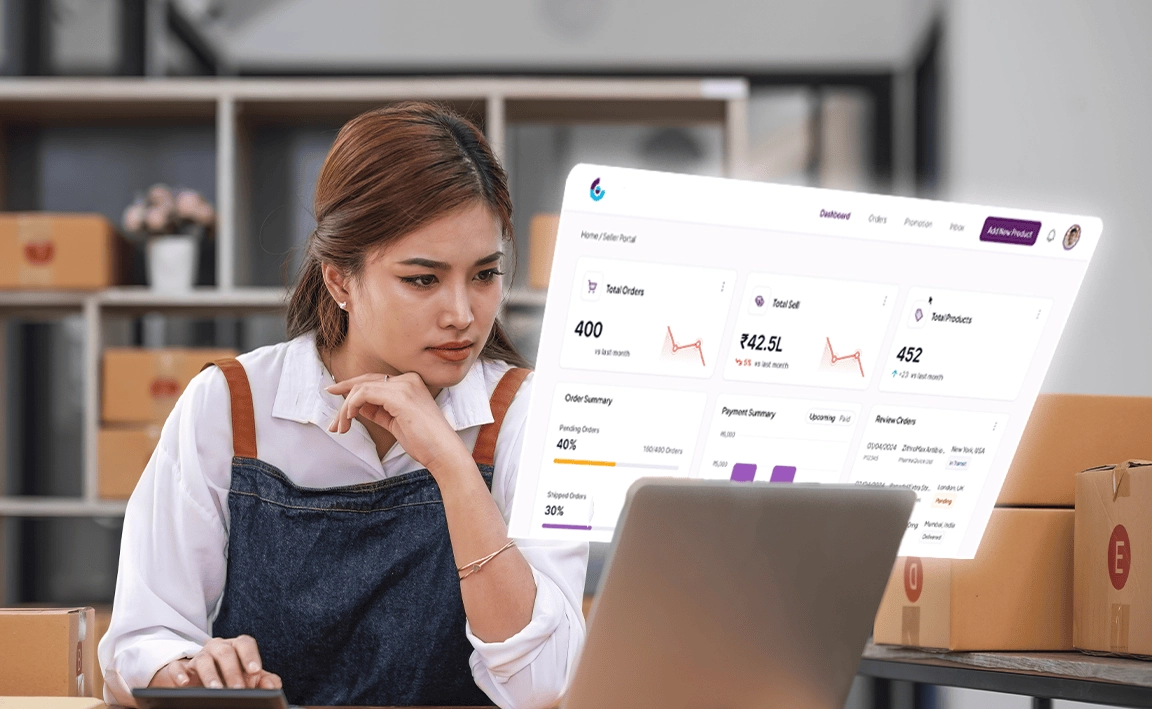

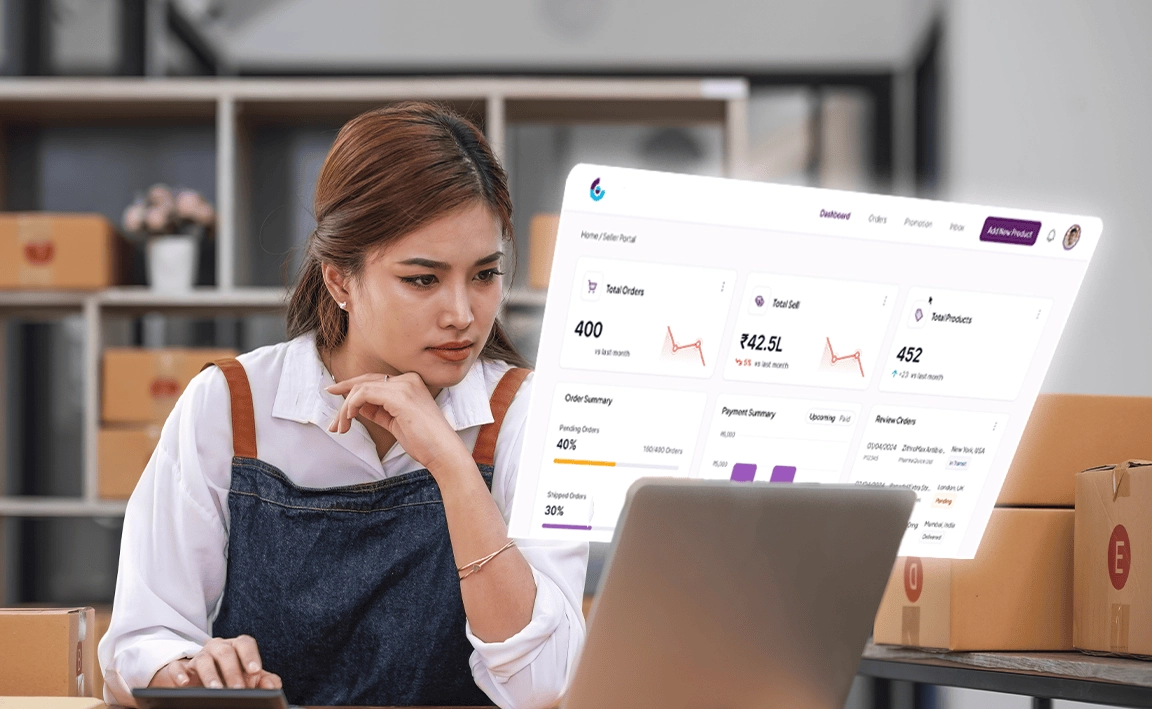

Optimize your FMCG logistics with Ninja Van’s end-to-end solutions

From first-mile pickup to warehousing, middle-mile transfers, and last-mile delivery, we streamline every step of the journey to ensure speed, efficiency, and cost-effectiveness. Our tech-enabled approach enhances visibility, reduces delays, and helps you build a resilient, adaptable supply chain that keeps up with consumer demand. Partner with Ninja Van and move your FMCG products smarter, faster, and with greater reliability—driving more growth for your business.

The Ninja Van Advantage

.webp)

Ninja Fulfillment

Ninja Fulfillment optimizes first-mile delivery, ensuring seamless warehousing and fulfillment to keep your supply chain running smoothly.

.webp)

Ninja Restock

Ninja Restock streamlines middle-mile delivery, ensuring cost-efficient, timely inventory restocking between warehouses and retail outlets.

Ninja Dash

Ninja Dash ensures fast, efficient last-mile delivery, enabling quick door-to-door delivery with nationwide smart routing and a dedicated fleet.

Trusted by Leading Brands, E-Commerce Platforms, and Institutions

Explore Expert Perspectives on the Ever-Changing Logistics Landscape

Double-Digit Sale in the Philippines

Double-digit sale days in the Philippines are your golden opportunity to boost sales and maximize profits, especially during the holiday rush. Get expert tips and strategies in this quick guide!

Read more

.webp)

Secure Document Delivery: Compliance for Finance & Government

Secure your document distribution with trusted logistics. Meet bidding requirements for finance and government with ePOD, bulk tracking, and Ninja Dash.

Read more

.webp)

The LTL Advantage for Retailers

Reduce retail logistics costs by 30% with LTL replenishment. Improve OSA and DOT to 98% using Ninja Restock and scan-to-print technology nationwide.

Read more

.webp)

Multi-Brand Logistics Distribution in the Philippines

Scale multi-brand growth with E2E logistics. Use regional hubs and Ninja Van Services to manage inventory and improve supply chain efficiency nationwide.

Read more

.webp)

Technology for Smarter Delivery in the Philippines

A look at delivery partners' technologies, such as scan-to-print, automated sorting, tracking tools, and API integration, helps Filipino sellers handle rising parcel volume.

Read more

.webp)

Smart Fulfillment for Scaling Businesses in the Philippines

Learn how smart fulfillment helps scaling businesses handle stock, dispatch work, and nationwide delivery, with insights linked to the Philippine ecommerce market.

Read more

.webp)

Last-Mile Delivery for Business in the Philippines

A guide to last-mile delivery for FMCG, beauty, and fashion teams' business for fast runs, tracking, and parcel handling.

Read more

Connecting Warehouses to Retail in the Philippines

Discover practical strategies to connect warehouses and retail stores efficiently. Learn how route optimization, co-loading, and real-time tracking improve logistics.

Read more

.webp)

Optimizing B2B Restocking with Ninja Restock Solutions

Learn how flexible B2B restocking models, SLA customization, and automation tech enhance supply chain efficiency and support modern trade logistics.

Read more

.webp)

Smarter FMCG Fulfillment in the Philippines

Discover how smarter, tech-driven fulfillment systems help FMCG brands in the Philippines streamline operations, reduce costs, and meet growing consumer demand.

Read more

How Filipino Shopping Behaviors Shape E-Commerce Fulfillment

Discover how Philippines consumer habits like live-selling, COD, and fast delivery impact e-commerce fulfillment. Learn practical ways to adapt your business for growth.

Read more

Driving B2B Inventory Efficiency for Philippine Retail

Explore B2B inventory strategies for PH supermarkets, mini-marts, and convenience stores. Learn how to boost efficiency and cut costs with smart logistics solutions.

Read more

.webp)

Hidden Costs of Order Fulfillment in the Philippines

Discover the hidden costs of order fulfillment in the Philippines. Learn tips to reduce expenses, improve efficiency, and choose the fulfillment partner for your business.

Read more

.webp)

Peak Season Fulfillment: How to Handle Seasonal Demand

Get smart strategies for peak season fulfillment in the Philippines. Stock early, ship quickly, and stay ahead of rising holiday demand nationwide.

Read more

.webp)

Same-Day Delivery in the Philippines

Same-day delivery in the Philippines is changing the game. Learn how to use it to boost speed, sales, and customer satisfaction.

Read more

Just-in-Time Inventory: Is It Right for Your Business?

Running out of space or stock too soon? Just-in-time inventory management could be your fix—cut costs and keep shelves stocked without the excess.

Read more

Your 2025 Guide to Scaling E-Commerce in the Philippines

This guide delivers a strategic roadmap to scale your e-commerce business through logistics, fulfillment, customer support, inventory, and digital growth.

Read more

.webp)

The Impact of Returns in E-Commerce

High e-commerce return rates hurt profits, especially for bulky items. Learn how to reduce the cost of returns and improve operations in this guide.

Read more

.webp)

How Businesses Handle Last-Mile Logistics for Bulky Items

Delivering big items comes with challenges that can rapidly cut into profits when you're unprepared. Learn more in this guide!

Read more

.webp)

How Filipino Businesses Can Prevent Inventory Gaps

Prevent costly stockouts with strategic planning and effective logistics. Learn replenishment strategies tailored for growing Filipino businesses.

Read more

How to Ship Bulky Items in the Philippines

Learn how to ship bulky items in the Philippines with smart strategies, cost-saving tips, and the best delivery options for your business.

Read more

Bulky Shipping in the Philippines: Challenges, Costs, and Tips

Bulky items are often hard to ship. How do you handle delivering them to customers? Learn the best way to ship heavy boxes here.

Read more

%20(1).webp)

The Business Case for Outsourcing Logistics

Cut logistics costs, boost efficiency, and streamline your operations. Discover how Ninja Van's solutions help your business thrive.

Read more

.webp)

Evolving Role of Tech Enablement in Logistics

Discover how Ninja Van’s tech-enabled logistics solutions can streamline your fulfillment & warehousing. Stay competitive with real-time tracking and efficient delivery.

Read more

.webp)

How Third-Party Logistics Transforms Business

Explore how 3PL providers offer advanced logistics solutions, from inventory management and real-time tracking to faster delivery options.

Read more

.webp)

Why Co-Loading is the Future of B2B Delivery

In the fast-paced world of B2B logistics, inefficiencies can slow down business operations—especially in high-demand areas like the Greater Manila Area. One major challenge? Paying for an entire truck when you only need a fraction of the space.

Read more

What is Last Mile Delivery?

Last-mile delivery is often the most time-consuming and expensive part of logistics. With increasing customer expectations, businesses need cost-effective, scalable solutions to ensure faster delivery times, flexible parcel handling, and seamless integration.

Read more

How to Optimize Interisland Shipping

Interisland shipping is essential for businesses in the Philippines, but challenges like schedule delays and limited capacity can disrupt operations. This guide explores the challenges, solutions, and best practices for optimizing RoRo shipping.

Read more

LTL vs. FTL Shipping

Choosing between LTL and FTL can impact your logistics efficiency, costs, and customer satisfaction. This guide breaks down their key differences, benefits, and best use cases—helping you optimize inventory movement.

Read more

Supply Chain Challenges in Inventory Logistics

Supply chain challenges can impact business success, with geography, and seasonality adding complexity. This guide explores cost-effective solutions to streamline operations and optimize costs.

Read more

Double-Digit Sale in the Philippines

Double-digit sale days in the Philippines are your golden opportunity to boost sales and maximize profits, especially during the holiday rush. Get expert tips and strategies in this quick guide!

Read more

.webp)

Secure Document Delivery: Compliance for Finance & Government

Secure your document distribution with trusted logistics. Meet bidding requirements for finance and government with ePOD, bulk tracking, and Ninja Dash.

Read more

.webp)

The LTL Advantage for Retailers

Reduce retail logistics costs by 30% with LTL replenishment. Improve OSA and DOT to 98% using Ninja Restock and scan-to-print technology nationwide.

Read more

.webp)

Multi-Brand Logistics Distribution in the Philippines

Scale multi-brand growth with E2E logistics. Use regional hubs and Ninja Van Services to manage inventory and improve supply chain efficiency nationwide.

Read more

.webp)

Technology for Smarter Delivery in the Philippines

A look at delivery partners' technologies, such as scan-to-print, automated sorting, tracking tools, and API integration, helps Filipino sellers handle rising parcel volume.

Read more

.webp)

Smart Fulfillment for Scaling Businesses in the Philippines

Learn how smart fulfillment helps scaling businesses handle stock, dispatch work, and nationwide delivery, with insights linked to the Philippine ecommerce market.

Read more

.webp)

Last-Mile Delivery for Business in the Philippines

A guide to last-mile delivery for FMCG, beauty, and fashion teams' business for fast runs, tracking, and parcel handling.

Read more

Connecting Warehouses to Retail in the Philippines

Discover practical strategies to connect warehouses and retail stores efficiently. Learn how route optimization, co-loading, and real-time tracking improve logistics.

Read more

.webp)

Optimizing B2B Restocking with Ninja Restock Solutions

Learn how flexible B2B restocking models, SLA customization, and automation tech enhance supply chain efficiency and support modern trade logistics.

Read more

.webp)

Smarter FMCG Fulfillment in the Philippines

Discover how smarter, tech-driven fulfillment systems help FMCG brands in the Philippines streamline operations, reduce costs, and meet growing consumer demand.

Read more

How Filipino Shopping Behaviors Shape E-Commerce Fulfillment

Discover how Philippines consumer habits like live-selling, COD, and fast delivery impact e-commerce fulfillment. Learn practical ways to adapt your business for growth.

Read more

Driving B2B Inventory Efficiency for Philippine Retail

Explore B2B inventory strategies for PH supermarkets, mini-marts, and convenience stores. Learn how to boost efficiency and cut costs with smart logistics solutions.

Read more

.webp)

Hidden Costs of Order Fulfillment in the Philippines

Discover the hidden costs of order fulfillment in the Philippines. Learn tips to reduce expenses, improve efficiency, and choose the fulfillment partner for your business.

Read more

.webp)

Peak Season Fulfillment: How to Handle Seasonal Demand

Get smart strategies for peak season fulfillment in the Philippines. Stock early, ship quickly, and stay ahead of rising holiday demand nationwide.

Read more

.webp)

Same-Day Delivery in the Philippines

Same-day delivery in the Philippines is changing the game. Learn how to use it to boost speed, sales, and customer satisfaction.

Read more

Just-in-Time Inventory: Is It Right for Your Business?

Running out of space or stock too soon? Just-in-time inventory management could be your fix—cut costs and keep shelves stocked without the excess.

Read more

Your 2025 Guide to Scaling E-Commerce in the Philippines

This guide delivers a strategic roadmap to scale your e-commerce business through logistics, fulfillment, customer support, inventory, and digital growth.

Read more

.webp)

The Impact of Returns in E-Commerce

High e-commerce return rates hurt profits, especially for bulky items. Learn how to reduce the cost of returns and improve operations in this guide.

Read more

.webp)

How Businesses Handle Last-Mile Logistics for Bulky Items

Delivering big items comes with challenges that can rapidly cut into profits when you're unprepared. Learn more in this guide!

Read more

.webp)

How Filipino Businesses Can Prevent Inventory Gaps

Prevent costly stockouts with strategic planning and effective logistics. Learn replenishment strategies tailored for growing Filipino businesses.

Read more

How to Ship Bulky Items in the Philippines

Learn how to ship bulky items in the Philippines with smart strategies, cost-saving tips, and the best delivery options for your business.

Read more

Bulky Shipping in the Philippines: Challenges, Costs, and Tips

Bulky items are often hard to ship. How do you handle delivering them to customers? Learn the best way to ship heavy boxes here.

Read more

%20(1).webp)

The Business Case for Outsourcing Logistics

Cut logistics costs, boost efficiency, and streamline your operations. Discover how Ninja Van's solutions help your business thrive.

Read more

.webp)

Evolving Role of Tech Enablement in Logistics

Discover how Ninja Van’s tech-enabled logistics solutions can streamline your fulfillment & warehousing. Stay competitive with real-time tracking and efficient delivery.

Read more

.webp)

How Third-Party Logistics Transforms Business

Explore how 3PL providers offer advanced logistics solutions, from inventory management and real-time tracking to faster delivery options.

Read more

.webp)

Why Co-Loading is the Future of B2B Delivery

In the fast-paced world of B2B logistics, inefficiencies can slow down business operations—especially in high-demand areas like the Greater Manila Area. One major challenge? Paying for an entire truck when you only need a fraction of the space.

Read more

What is Last Mile Delivery?

Last-mile delivery is often the most time-consuming and expensive part of logistics. With increasing customer expectations, businesses need cost-effective, scalable solutions to ensure faster delivery times, flexible parcel handling, and seamless integration.

Read more

How to Optimize Interisland Shipping

Interisland shipping is essential for businesses in the Philippines, but challenges like schedule delays and limited capacity can disrupt operations. This guide explores the challenges, solutions, and best practices for optimizing RoRo shipping.

Read more

LTL vs. FTL Shipping

Choosing between LTL and FTL can impact your logistics efficiency, costs, and customer satisfaction. This guide breaks down their key differences, benefits, and best use cases—helping you optimize inventory movement.

Read more

Supply Chain Challenges in Inventory Logistics

Supply chain challenges can impact business success, with geography, and seasonality adding complexity. This guide explores cost-effective solutions to streamline operations and optimize costs.

Read more

Double-Digit Sale in the Philippines

Double-digit sale days in the Philippines are your golden opportunity to boost sales and maximize profits, especially during the holiday rush. Get expert tips and strategies in this quick guide!

Read more