Lowering Replenishment Costs: The LTL Advantage for Multi-Branch Retailers

.webp)

Every multi-branch retailer in the Philippines eventually faces the same dilemma: how to keep shelves stocked without spending a fortune. It is a difficult balancing act. If you wait for enough orders to fill a massive truck, your shelves sit empty and you lose sales. But if you send half-empty trucks just to maintain availability, your transport costs eat your profits.

This "Retailer’s Dilemma" is a major reason why logistics expenses in the Philippines consume an alarming 27% of sales revenue, more than double the rate of our ASEAN neighbors¹. With the country's total logistics costs sitting at 27.5% of GDP, these inefficiencies aren't just an operational headache; they are a direct hit to your bottom line.

The goal for any growing retail business is to improve On-Shelf Availability (OSA). You want the right products in the right place at the exact moment a customer wants to buy them. Achieving this requires smarter, more frequent replenishment.

Many successful retailers are now taking a more flexible approach, using LTL for frequent replenishment and FTL for larger planned moves. When you match the shipment type to the load, you can protect on-shelf availability while keeping replenishment costs under control.

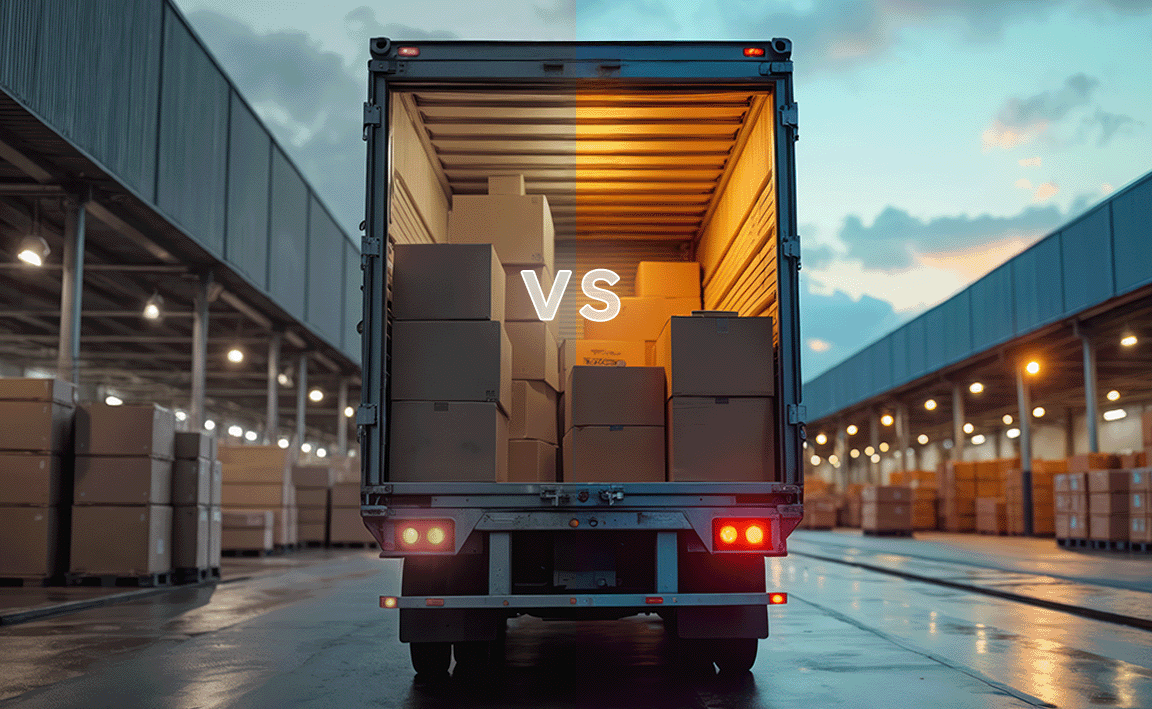

The Financial Math: FTL vs. LTL in Branch Resupply

To understand why retailers are making the switch, you have to look at the waste hidden in traditional shipping. In a standard FTL model, you pay for the entire vehicle regardless of how much inventory is inside. If a branch only needs a few pallets of stock but you send a large truck, you are effectively "paying for air." This unused volume is a major source of waste, especially for weekly replenishment where orders are rarely large enough to fill a heavy vehicle.

The LTL solution through Ninja Van Philippines changes this math entirely. Instead of paying for the whole truck, you pay only for the space you actually use, calculated on a per-cubic-meter (cbm) or per-case basis.

Why LTL is More Cost-Effective for Retail:

- Pay Only for Space: You are no longer penalized for smaller, more frequent orders.

- Reduced Overhead: You don't need to manage a massive private fleet that sits idle half the time.

- Better Cash Flow: Frequent, smaller deliveries mean you don't have to tie up all your capital in massive amounts of inventory sitting in a backroom.

The results are measurable. Businesses that move to a flexible LTL model often see at least 30% cost savings on their logistics expenses. This directly improves your Cost-to-Sale (CTS). When you reduce the cost of moving an item from the warehouse to the store, your profit on every sale increases. In a competitive market, a 30% reduction in transport costs provides the breathing room needed to scale your branch network.

When FTL Still Makes Sense

FTL remains a strong option when you can fully utilize the truck, such as major inventory restocks, relocations, or peak-season replenishment. In these cases, FTL can be efficient because you are moving a high volume in one run and reducing the number of separate trips.

The key is choosing the right model for the job.

- LTL for smaller, more frequent branch restocks

- FTL when you have enough volume to fill a truck.

Solving the On-Shelf Availability (OSA) Challenge

Keeping products on the shelf is the most basic requirement of retail, yet it is often the hardest to execute. If a customer sees an empty shelf twice, they likely won't come back a third time. Solving this requires a move toward more modern replenishment tactics.

1. Moving from "Milk Runs" to Simultaneous Deliveries

The old way of restocking involves "milk runs." One truck leaves the warehouse and visits five different stores in a single day. The problem with this model is that it is slow and prone to delays. If the first store has a long unloading time or if there is a traffic accident on the way to the second branch, every subsequent store on the route suffers.

The Ninja Restock model replaces this with centralized cross-docking. Instead of one truck making multiple stops, orders are sorted at a central hub and dispatched through a massive network. This allows for simultaneous deliveries across multiple store Receiving & Dispatch Units (RDUs). Every branch gets its stock independently, ensuring that a delay at Store A never impacts Store B.

2. Achieving 98% On-Time Delivery (DOT)

In the B2B world, being "on-time" isn't specific enough. A delivery is only successful if it arrives on the Requested Arrival Date (RAD). Many traditional providers struggle to maintain a consistent Delivery On-Time (DOT) rate, often hovering around a 93% baseline.

By utilizing a dedicated B2B network, retailers can push that DOT rate to 98%¹. This 5% gap might seem small, but it is vital. Moving from 93% to 98% DOT ensures that your customers never see an empty shelf. It means your store staff can plan their day around a reliable delivery schedule, rather than waiting for a truck that might not show up until after the store has closed.

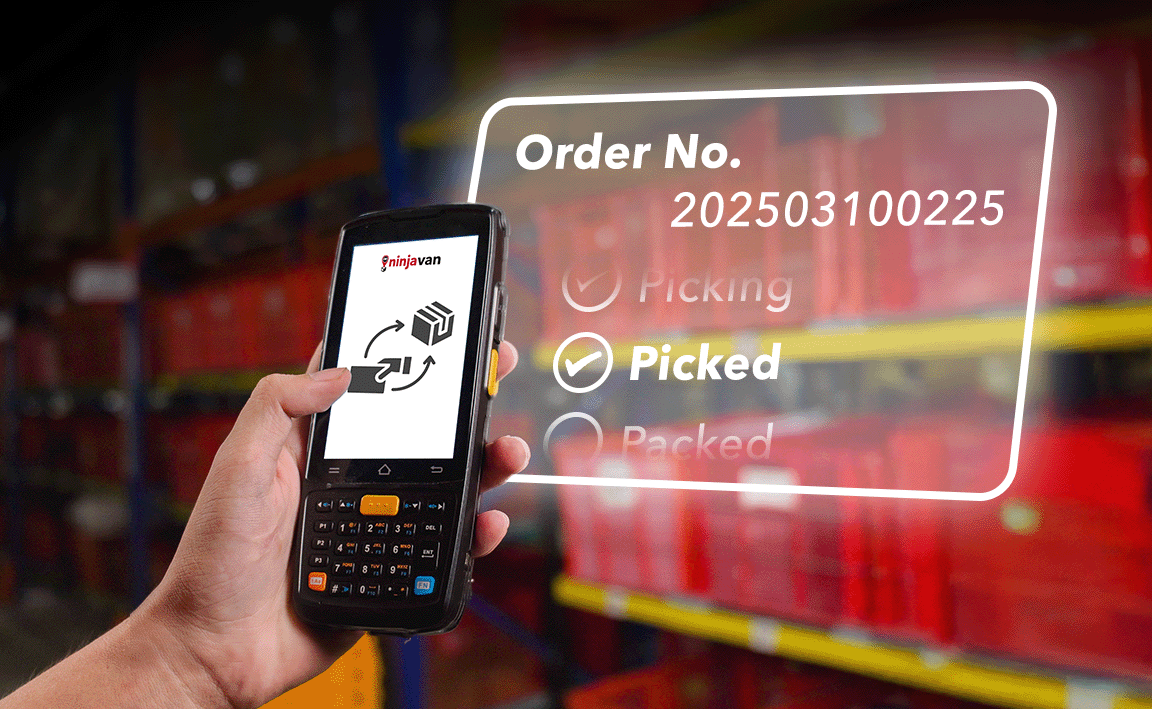

3. Reducing Sorting Errors with Scan-to-Print Tech

Manual sorting is a major bottleneck. When warehouse staff have to manually label and sort thousands of cases for different branches, mistakes happen. This leads to "wrong store, wrong item" errors, where a branch receives inventory they didn't order while their actual stock is sent to the wrong city.

Ninja Van’s scan-to-print technology removes this human error.

- Every case is scanned at the sorting facility.

- A unique shipping label is generated instantly based on the system data.

- The item is tracked to the correct branch with total accuracy.

This tech-driven precision allows high-volume retailers to manage complex inventories across dozens of locations without losing control of their stock.

3 Strategies to Optimize Your Restock Workflow

If you are looking to improve your branch profitability, consider these three strategies:

- Prioritize High-Turnover SKUs for LTL Frequency: Use LTL to increase the delivery frequency for your fast-moving items. This keeps your stock levels low—reducing the capital tied up in inventory—while ensuring the products are always available for customers.

- Use Regional Hubs to Shorten the "Last Mile": Staging your inventory closer to the final retail location through Ninja Fulfillment reduces lead times and transport costs. The shorter the distance between the hub and the branch, the more responsive your supply chain becomes.

- Monitor OTIF (On-Time, In-Full) Metrics Weekly: Use data to identify branch-specific bottlenecks. If one branch consistently has issues receiving stock, the data will show you why. Weekly monitoring allows you to continuously improve the replenishment process and hold your logistics partner accountable.

- Use FTL for Bulk Moves, LTL for Branch Replenishment: Use FTL for planned bulk movements such as warehouse-to-warehouse transfers, seasonal ramp-ups, or major restocks where the truck is fully utilized. Then use LTL for regular branch replenishment to avoid paying for unused space and to maintain steady on-shelf availability. This hybrid approach helps you balance cost, speed, and stock reliability.

Smart Fulfillment for Modern Retail

Profitability in multi-branch retail is won in the supply chain. If you wait to fill a full truck, shelves can run empty. If you send half-full trucks, transport costs climb. That’s why many retailers shift from FTL to LTL to restock more often without paying for unused space.

Ninja Restock combines the technology and nationwide network to make LTL replenishment practical at scale. You can move smaller loads more frequently, protect on-shelf availability, and keep replenishment costs under control.

At the same time, FTL still has its place. For major inventory restocks or relocations where a full truck is utilized, we’re open to supporting FTL shipments as long as requirements are met. In short: LTL for flexible replenishment, FTL for bulk moves, across Metro Manila, GMA, and beyond.